ARS Hip & Ridge Strip For Roof Felt Shingles 9 l/m Black / Green / Red

In stock

Lead time confirmed upon order

Don't just compare product prices

Our low delivery rates mean your total order cost is often less than you'd expect. Check delivery rates on the basket page.

Right product for your project?

Talk to an expert. Call us on 01737 763008.

Want to buy in large quantities?

Call us on 01737 763008 to discuss bulk pricing.

FREE Click & Collect

Simply proceed to the checkout and select one of our stores: Dorking (Surrey), Redhill (Surrey), East Grinstead (Sussex) and Esher (Surrey).

Details

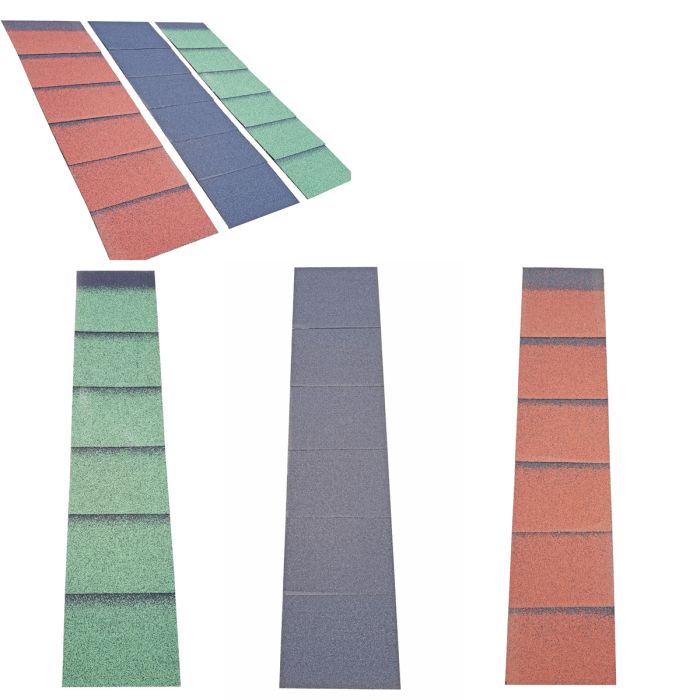

ARS Hip & Ridge Strip For Roof Felt Shingles 9 l/m Black / Green / Red

For use on Hip and ridge details by laying over the hexagonal / scalloped shingles at the hips and ridges to both seal and finish the joint.

Click here to download installation and fixing details for the ARS Felt Shingle range

Fixing

To lay these shingles at pitches greater than 15 degrees:

- Lay the felt with at least a 75mm lap on the joints.

- Fix the felt to the board using 3mm to 3.5mm diameter barbed hot dipped galvanized roofing nails with a minimum 10mm head.

- Nails must be long enough to penetrate a minimum of 20mm into the solid wood deck or just through the plywood deck

- Staples are not recommended

- Raised nails can result in shingle distortion and may prevent sealing

- Drive the nails until they are flush with the surface but do not overdrive nails

- Do not nail into the sealing strip as the nails may prevent proper sealing

- Do not drive nails at an angle

To lay these shingles at pitches between 8 degrees and 15 degrees:

- Use a suitable underlay for the shingles such as either a quality shed felt, or better still a quality 3B Underlay felt (available separately).

- Lay the felt with at least a 100mm lap on the joints.

- Fix the felt to the board using 3mm to 3.5mm diameter barbed hot dipped galvanized roofing nails with a minimum 10mm head or glue the felt down using bitumen adhesive.

- Nails must be long enough to penetrate a minimum of 20mm into the solid wood deck or just through the plywood deck

- Staples are not recommended

- Raised nails can result in shingle distortion and may prevent sealing

- Drive the nails until they are flush with the surface but do not overdrive nails

- Do not nail into the sealing strip as the nails may prevent proper sealing

- Do not drive nails at an angle

Ridges / Hips:

- These are made from the strips of shingles, by cutting the strips into the individual tile shaped "tabs" and then overlaying them over each other along the ridges or hips.

- This simple method reduces wastage as you are able to use your offcuts rather than having to throw them away!

- Alternatively, you can make an allowance for the hips / ridge when estimating your requirements by allowing for 2.4 strips of shingles per linear metre of ridge / hip.

Technical specification

Technical

- Minimum Pitch: 15 degrees

- Can be used down to 8 degrees if an underlay is used beneath this product

- Supplied in packs of 20 strips

- Dimensions: 1.0m x 0.25m /strip

- Perforated (so they can be easily cut / pulled into 3 usable pieces)

- Backing: Self adhesive

Related Articles

-

-

-

-

-

-

-